Semiconductor & Hard Disk Testing

As quality and throughput demands continue to dominate the semiconductor industry, faster and more accurate scanning and measurement equipment is required.

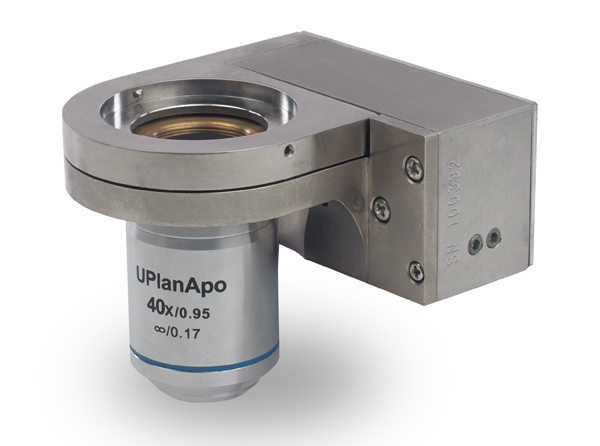

Queensgate nanopositioning systems offer market-leading accuracy, and our systems operate with repeatability in the nanometer range together with response times below one millisecond. Our velocity control allows image collection at speeds greater than 1000 μm/s.

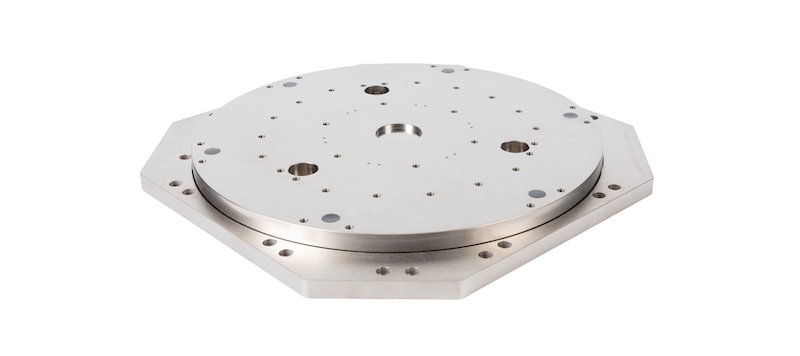

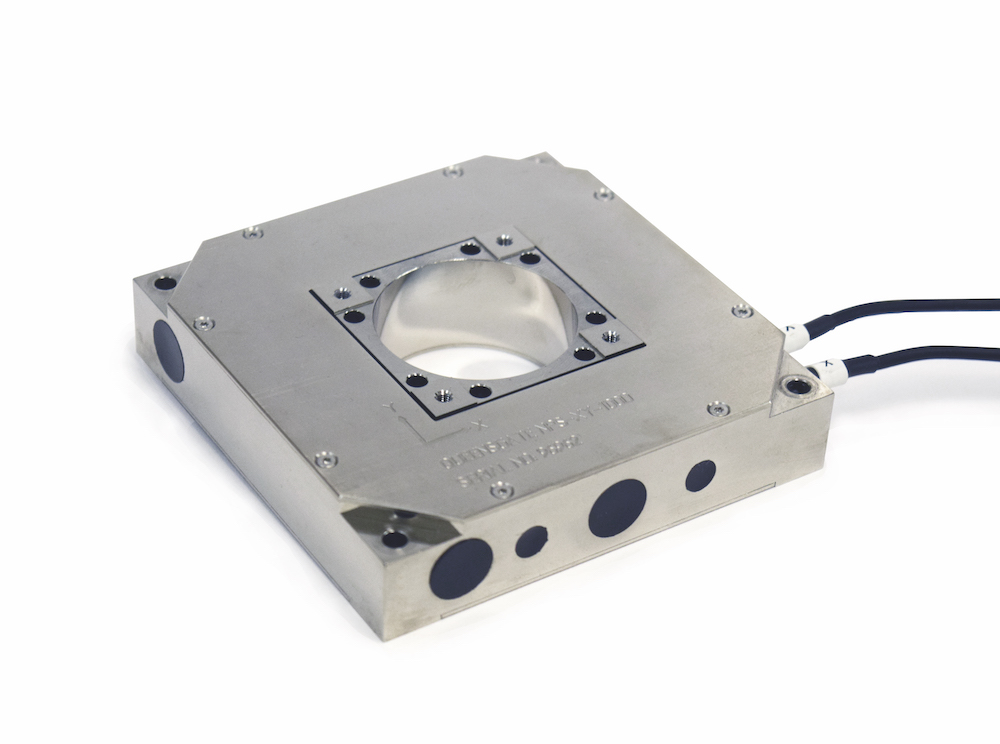

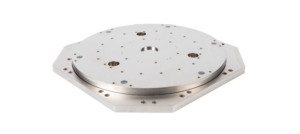

Surface inspection – quality control for semiconductor manufacture

For optical inspection of semiconductor wafers the ability to move large, heavy loads with nanometer precision, at high speed with exceptional repeatability is essential. Our WP120A wafer stage is capable of holding wafers weighing up to 14 kg offering a resolution of 1.5 nm.

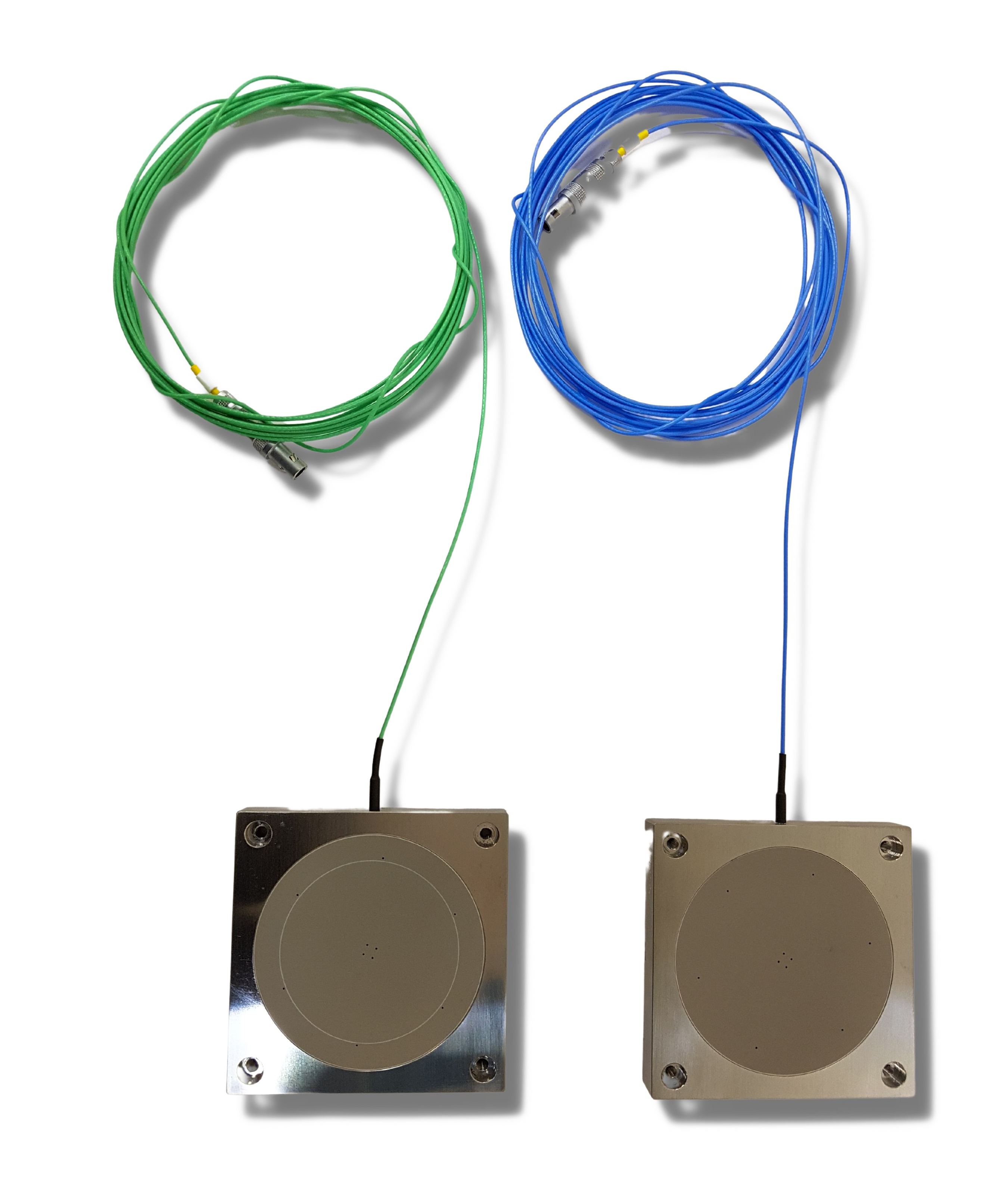

We deliver high quality sensors, translators and stages to the world’s leading producers for use in a whole host of processes including:

- UV, EUV, E-beam and X-Ray

- Mask and wafer inspection systems (including critical dimension CD)

- Mask and wafer manufacturing systems

- Wafer chuck nanometer alignment, measurement and control

- Mask and wafer manufacturing systems

- Auto focusing

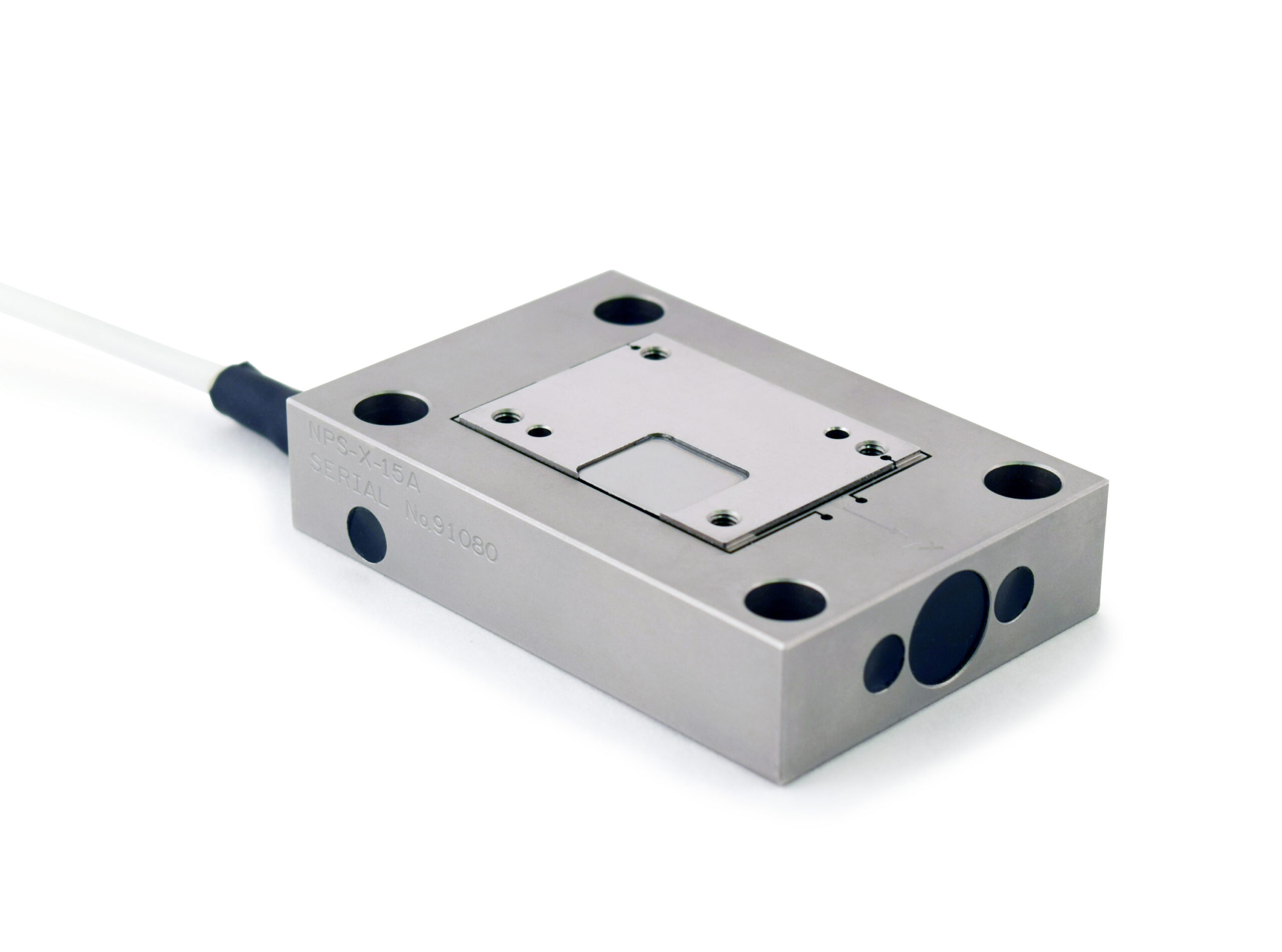

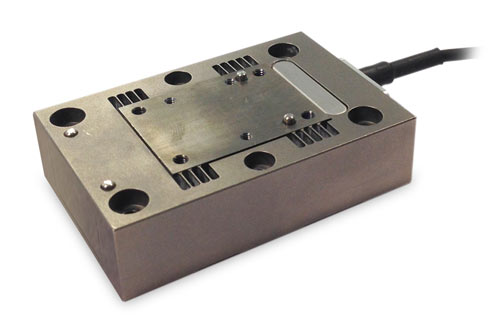

Hard disk drive testing

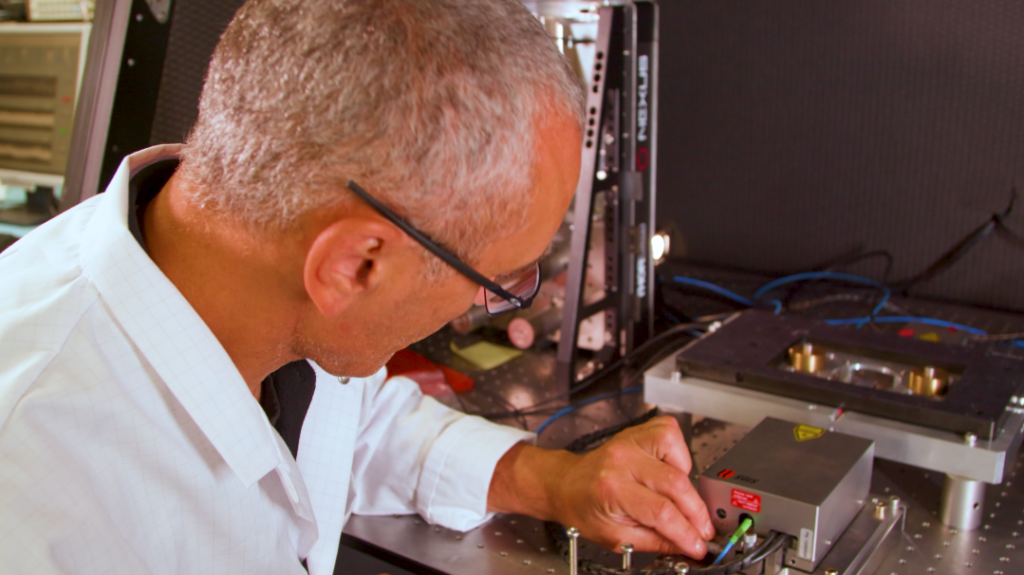

Queensgate designed a custom stage and controller for a hard disk drive (HDD) read/write head testing system to meet the production’s high quality and precision needs. The factory tests about one million heads per day before building them into the final hard disk drives.

The demands of the test equipment are aligned with the final HDD’s performance. Consumer expectations for product performance are high and ever-advancing. When the product specifications change, so change the demand for the testing equipment. The total position error budget for testing is currently less than 0.5 nm, requiring measurement at the angstrom level. When operating with small margins, everything from conversations in the same room to fractional degrees of temperature change affects positioning.

Download the High Speed, High Precision Applications brochure