NanoScan OP200 Piezo Objective Positioner / Scanner

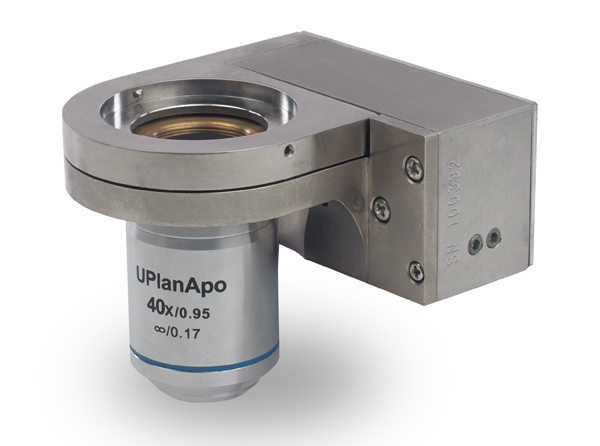

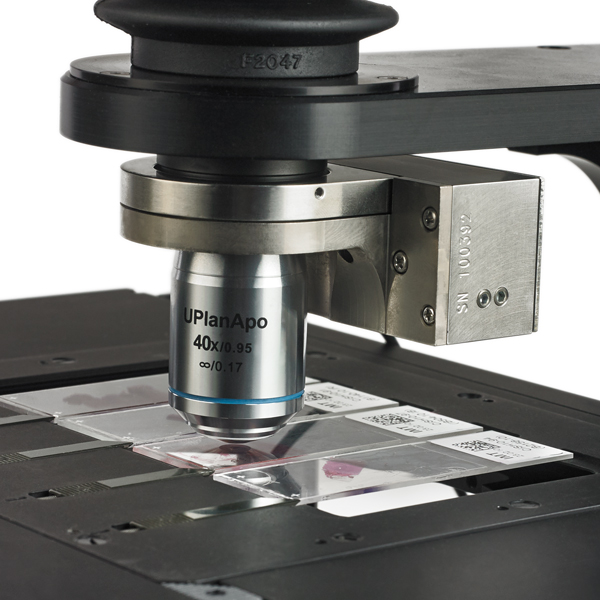

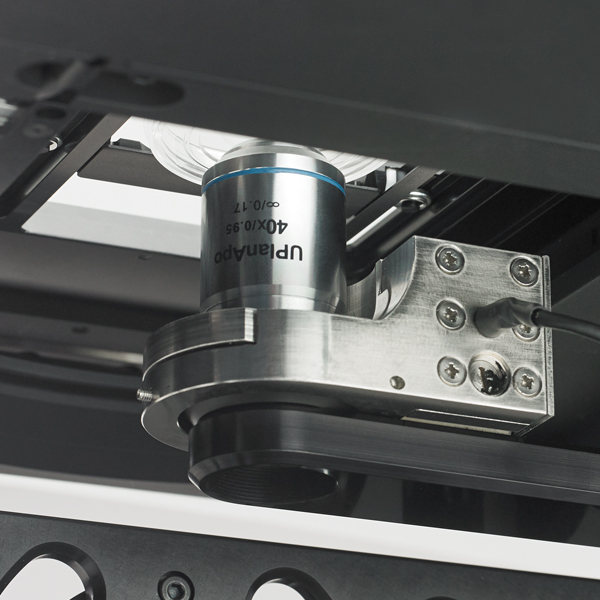

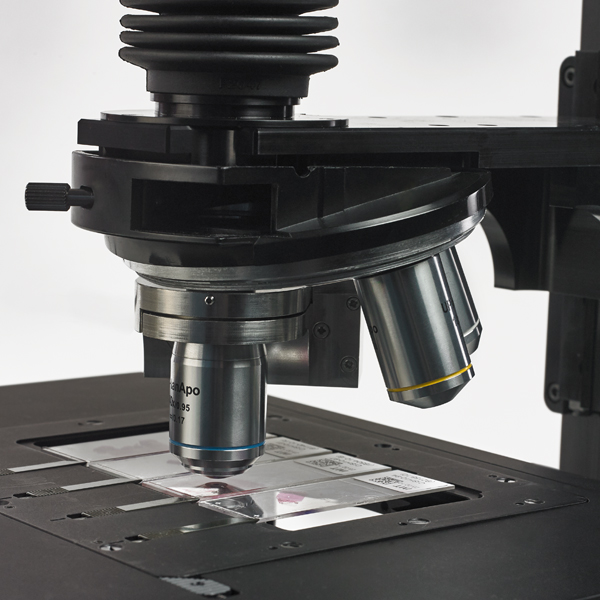

The NanoScan OP200 piezo-driven objective positioner is compatible with most commercial and customized microscopes. The stage features an M32 objective thread as standard with a wide range of adapters available.

Its high stiffness (1.3 N/µm) provides class-leading step settle performance over a range of up to 200 µm. It features capacitive feedback sensors that ensure exceptional repeatability and resolution.

Settings for inverted or upright operation and load capacity are set during manufacture and can be further tuned in the field to optimize for specific applications.

Customized mounting and objective holders for OEM applications are available on request.

0-500 g load as standard. High and custom load tuning is available on request.

Suggested controllers

Download datasheet

NanoScan OP200 Piezo Objective Positioner / Scanner

The NanoScan OP200 piezo-driven objective positioner is compatible with most commercial and customized microscopes. The stage features an M32 objective thread as standard with a wide range of adapters available.

Its high stiffness (1.3 N/µm) provides class-leading step settle performance over a range of up to 200 µm. It features capacitive feedback sensors that ensure exceptional repeatability and resolution.

Settings for inverted or upright operation and load capacity are set during manufacture and can be further tuned in the field to optimize for specific applications.

Customized mounting and objective holders for OEM applications are available on request.

0-500 g load as standard. High and custom load tuning is available on request.

Suggested controllers

Download datasheet

Key features of the NanoScan OP200

- 200 μm closed-loop travel range (260 μm open loop range).

- High-stiffness (1.3 N/um) provides class-leading step-settle performance.

- Stainless steel construction provides greater mechanical stiffness and temperature stability.

- Capacitive positioning sensors used to give sub-nanometer positioning and the best resolution, stability, and repeatability.

- Connectors with built-in stage calibration provide plug-and-play electronics that can be interchanged, minimizing system downtime.

Applications

- Optical sectioning producing 3D images

- Autofocus systems for time lapse imaging

- High content screening

- Surface analysis

- Wafer inspection

- Scanning interferometry

- Multiphoton microscopy

| Model |

OP200 |

| Axis |

Z |

| Range |

200 μm |

| Resolution |

0.4 nm under 150 g load |

| Repeatability |

1 nm Slow PID, 50 μm step, 1SD |

| Linearity |

0.01 % |

| 5% Settle 0.5μm Step 150g/250g/500g Load |

6 ms / 9 ms / 12 ms |

| Material |

Stainless Steel |

| Thread |

RMS, M25, W26, M27, M32 |

OP200-EN-Datasheet

DOWNLOAD

OP200 INSTALLATION DRAWING

DOWNLOAD